In the world of machining and manufacturing, high-speed drilling stands as a testament to the evolution of industrial practices. However, such drilling procedures are not without their challenges. Among the critical elements that help streamline these processes is cutting oil, an often overlooked yet fundamental component.

High-speed drilling, by its nature, involves a lot of friction and heat due to the rapid interaction between the drill bit and the workpiece. This heat buildup can adversely affect both the tool and the material being worked on, leading to premature tool wear and a decrease in the quality of the finished product. That’s where cutting oils come in, performing several crucial roles to ensure smooth and efficient drilling.

Firstly, cutting oils act as a cooling agent. They effectively disperse the heat generated during high-speed drilling, reducing the temperature in the cutting zone. This cooling function prevents potential damage to the drill bit, allowing it to maintain its sharpness and effectiveness for more extended periods. In turn, this translates into reduced operational costs as it limits the frequency of tool replacements.

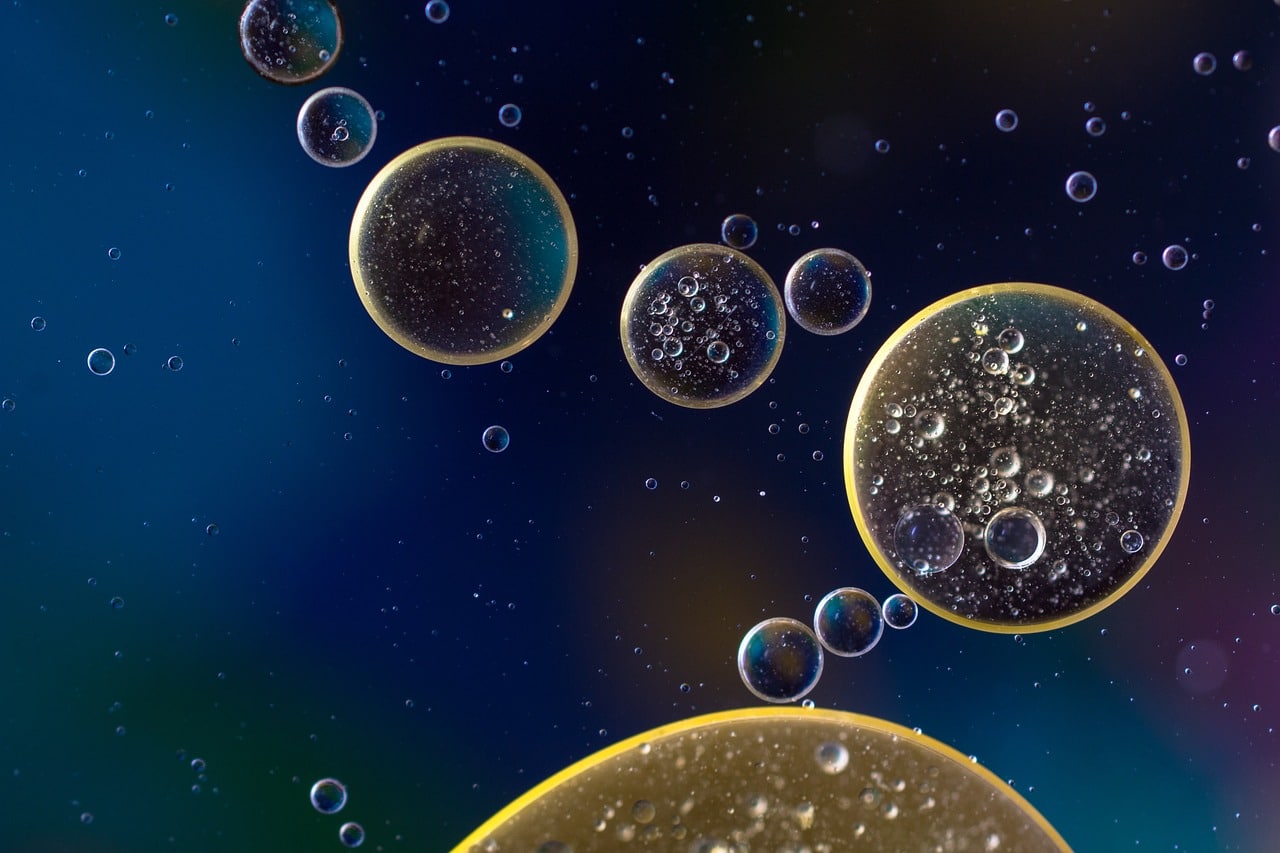

Additionally, cutting oils also serve as a lubricant. They minimize the friction between the drill bit and the workpiece, which not only lowers the heat generated but also prevents material from sticking to the tool. This lubricating property ensures a seamless drilling process and prevents interruptions that can occur due to material build-up on the drill bit.

A third benefit of cutting oils is their contribution to the quality of the finished product. By minimizing heat and friction, cutting oils help maintain the integrity of the material being drilled, preventing discoloration and warping. They also assist in cleaning the drilling site by carrying away the swarf—the tiny shavings or cuttings produced during drilling. This function ensures a cleaner work area, better finished surfaces, and an extended tool lifespan.

The selection of the right cutting oil is also a key consideration. Various factors can influence the effectiveness of a cutting oil, such as its viscosity, its additive composition, the material being drilled, and the specific parameters of the drilling operation. It’s important to match the right cutting oil with the given operation to maximize efficiency and product quality.

The Best Cutting Oil Brands for Your Metal Types

In the rugged arena of high-speed drilling, your cutting oil isn’t just a lubricant—it’s your trusted cornerman. It keeps the heat down, keeps your drill bit sharp, and helps you produce a cleaner, meaner cut. But not all cutting oils are cut from the same cloth, and your metal’s characteristics will dictate the brand of cutting oil you should be throwing into the mix.

- Castrol’s Variocut C Moly Dee: Castrol’s cutting oils, especially the Variocut C Moly Dee, have garnered a strong reputation in the market, and for a good reason. This heavy-duty, chlorine-free cutting oil excels when you’re drilling into tough materials like stainless steel. Its unique composition is high in extreme pressure (EP) additives, ensuring that you get a slick, smooth operation even under high loads.

- Fuchs Ecocool Series: When it’s aluminum in the crosshairs, the Fuchs Ecocool series is an ace up your sleeve. These cutting oils, specifically designed for non-ferrous metals, show unparalleled performance due to their special additive packages. Aluminum is a tricky customer, known for its ‘chip welding’ tendencies. But with Ecocool, you’re getting superior lubricity and excellent cooling properties, allowing you to land clean punches every time.

- Mobilmet Series: For a versatile contender that takes on a broad range of metals, the Mobilmet series comes out swinging. Whether it’s general steel, alloy steel, or even tough cast iron, these cutting oils perform admirably due to their high-performance additives. Plus, they boast a high degree of resistance to oxidation and excellent flushing characteristics, making them a reliable workhorse for varied drilling jobs.

- Hangsterfer’s S-500 CF: When drilling into titanium—a notoriously hard and heat-intensive metal—the Hangsterfer’s S-500 CF is your go-to guy. This cutting oil is specially formulated to handle the high heat and pressure of working with titanium. Its chlorine-free composition, combined with a proprietary mix of EP additives, gives it the edge needed to efficiently and effectively machine this demanding metal.

Remember, high-speed drilling is like a high-stakes boxing match. You need to equip yourself with the right cornerman—your cutting oil—to keep your operations smooth and your output top-notch. It’s not just about going hard and fast; it’s about drilling smart. Choose the right cutting oil brand for your metal, and you’re sure to be the reigning champ of your workshop. Remember, the only thing tougher than the metal you’re working with should be you—and the cutting oil you choose.

In conclusion, cutting oils are vital players in the high-speed drilling process. They address the challenges of heat and friction, ensuring the durability of tools, the quality of the end product, and overall operational efficiency. By recognizing and leveraging their essential role, manufacturers can optimize their high-speed drilling procedures to achieve better results.