Table of Contents

Hex drill bits have long been a staple in the toolboxes of craftsmen, hobbyists, and professionals alike. Their unique design and broad applicability have made them an essential tool in various industries. Let’s dive into their intriguing history, definition, and importance.

A Brief History of Hex Drill Bits

Tracing back to the early days of modern machining, hex drill bits emerged as a solution to a common problem: slippage inside the drill chuck. The six-sided design revolutionized the drilling process by offering a more secure grip, thus reducing wear and improving efficiency.

Definition and Uses

A hex drill bit is characterized by its six-sided shank, which is why it’s called ‘hex’ for hexagonal. Unlike traditional round-shanked bits, hex drill bits provide better torque and control, making them ideal for precise drilling tasks.

Their applications extend far and wide, from simple woodworking tasks to complex metal fabrications. Whether you are assembling furniture, installing fixtures, or creating intricate metal art, hex drill bits are up to the challenge.

Importance in Various Industries

Hex drill bits play a vital role in many industries, including construction, automotive, aerospace, and manufacturing. Their ability to provide precise drilling and ease of use has made them a go-to choice for professionals seeking accuracy and reliability.

From building skyscrapers to manufacturing automobile parts, hex drill bits have become an indispensable part of modern technology. Their adaptability and durability make them a favorite tool not just for professionals but for DIY enthusiasts as well.

Types of Hex Drill Bits

The world of hex drill bits is vast and diversified. Understanding different types is essential to choose the right bit for your project. Here, we explore the various types of hex drill bits, highlighting their unique properties and purposes.

Quick Connect Shanks

Quick connect shanks offer a fast and efficient way to change bits. Designed to snap into place without the need for additional tools, these bits save time and effort, making them a favorite for tasks requiring frequent bit changes.

Impact Rated

For heavy-duty applications, impact-rated hex drill bits are the way to go. Engineered to withstand high torque and force, they are suitable for drilling into robust materials, including concrete and metal.

Magnetic Properties

Some hex drill bits come with magnetic properties to hold screws or bits in place. This magnetic feature ensures that the screws don’t fall off the bit, especially when working in tight or awkward spaces. It adds an extra layer of convenience and efficiency.

Materials

Different materials are used to craft hex drill bits, each offering unique benefits. Common materials include:

- Steel: Durable and cost-effective, ideal for general use.

- Cobalt: Highly resistant to heat and wear, suitable for metal drilling.

How Hex Drill Bits Work

The intriguing mechanics behind hex drill bits can be understood by exploring their anatomy, functional mechanism, and the key differences between them and regular bits. This understanding lays the foundation for efficient use and optimal performance.

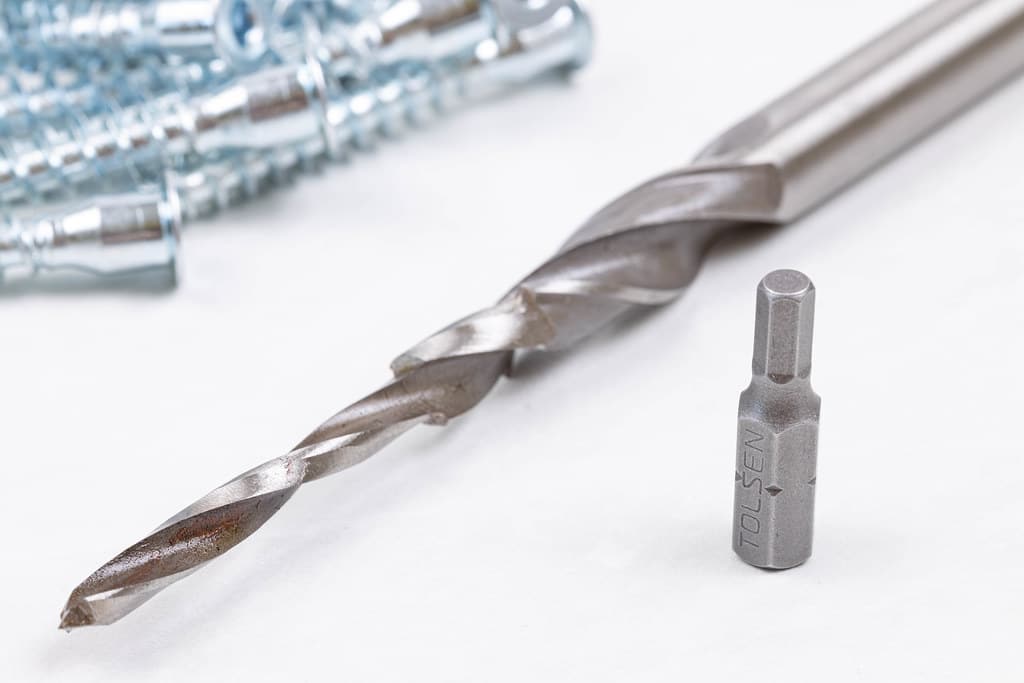

Anatomy of Hex Drill Bits

The design of hex drill bits is comprised of several key components:

- Shank: The hexagonal part that fits into the drill’s chuck, providing a secure grip.

- Flute: The grooves that allow material to escape while drilling.

- Tip: Often made of carbide or other hard materials, the tip does the actual cutting.

These components work in harmony to deliver precise and clean drilling.

Functional Mechanism

The working of hex drill bits is based on a simple yet effective mechanism. When the drill is activated, the bit rotates, and its tip cuts into the material. The hexagonal shape of the shank ensures that the torque is efficiently transferred, enabling effective drilling without slippage. The flutes channel the debris away from the drilling point, keeping the hole clean and the bit cool.

Difference Between Hex Drill Bits and Regular Bits

While hex drill bits and regular bits serve the same primary purpose, there are distinct differences:

- Torque Transfer: Hex drill bits provide better torque transfer due to their hexagonal shape, ensuring more forceful drilling.

- Slippage: The hexagonal design minimizes slippage, unlike cylindrical shanks.

- Versatility: Hex drill bits offer quicker changes and more compatibility with different drills.

These differences make hex drill bits a preferred choice for many applications.

Choosing the Right Hex Drill Bits

Choosing the right hex drill bits for a project is paramount to achieving the desired results. Various factors, including the material to be drilled, the type of drill being used, and the specific requirements of the job, need to be considered. Here’s a comprehensive guide.

Considerations for Purchasing

When selecting hex drill bits, consider the following:

- Material Compatibility: Match the bit material with the material to be drilled.

- Size: Select the appropriate diameter and length.

- Brand Quality: Opt for reputable brands to ensure durability and performance.

Top Brands of 2023

Some leading brands that have proven to be reliable include:

These brands offer a variety of options catering to different needs.

Common Sizes and Applications

Hex drill bits come in various sizes, each suited to specific tasks:

- 1/16-inch: Ideal for delicate tasks like jewelry making.

- 1/4-inch: Suitable for general household projects.

- 1/2-inch: Used for heavy-duty applications like drilling into concrete.

Using Hex Drill Bits: Tips and Techniques

Utilizing hex drill bits to their full potential requires mastering certain techniques and following specific tips. In this section, we will explore ways to optimize the performance of hex drill bits, ensuring safety, efficiency, and precision.

Preparation and Safety

Before beginning any drilling task, proper preparation and adherence to safety guidelines are crucial:

- Wear Safety Gear: Always wear appropriate safety equipment such as safety glasses and gloves.

- Choose the Right Bit: Select a hex drill bit that matches the material you intend to drill.

- Inspect the Tool: Ensure that the drill and bit are in good condition.

Techniques for Effective Drilling

Employing the right techniques can make a significant difference in the outcome of your project:

- Start Slow: Begin drilling at a slow speed to create a stable starting point.

- Apply Consistent Pressure: Use steady pressure to maintain control and avoid breakage.

- Use Lubrication if Necessary: For materials like metal, lubrication can reduce friction and extend bit life.

Troubleshooting Common Problems

Even with the best preparation and technique, you might encounter some common problems. Here’s how to handle them:

Maintenance and Care

Proper maintenance and care of hex drill bits extend their lifespan and preserve their efficiency. This section offers insights into regular maintenance practices, storage solutions, and ways to keep your hex drill bits performing at their best.

Regular Maintenance Practices

Regular care keeps hex drill bits in top condition:

- Cleaning: Wipe off debris and oil after each use.

- Sharpening: Sharpen the tips as needed to maintain cutting ability.

- Inspection: Regularly inspect for wear or damage.

Storage Solutions

Proper storage is key to preserving the quality of your bits:

- Use a Case: Store in a designated case to prevent damage.

- Keep Dry: Store in a dry place to prevent rusting.

Treating Common Wear and Tear

Over time, wear and tear are inevitable, but they can be treated effectively:

- Rust Removal: Use a rust remover or soak in vinegar and scrub with a brush.

- Re-sharpening: Utilize a proper sharpening tool or service to restore the bit’s edge.

Hex Drill Bits: Innovations and Future

Hex drill bits have been part of the tooling industry for quite some time, but their development has not stalled. With continuous technological advancements, new materials, and innovative design techniques, the future of hex drill bits is promising and dynamic. Here’s a glimpse into what’s on the horizon.

Materials and Manufacturing

The exploration of new materials and manufacturing techniques is leading to even more durable and efficient hex drill bits:

- Advanced Alloys: The development of new metal alloys with enhanced hardness and resistance to wear.

- 3D Printing: Utilizing 3D printing technology to create custom designs and geometries for specialized tasks.

- Coating Technologies: Innovative coatings that reduce friction and increase the lifespan of the bits.

Design and Ergonomics

Future designs of hex drill bits will likely emphasize user comfort and efficiency:

- Adaptive Geometry: Bits that can adapt to different materials and tasks.

- Ergonomic Shapes: Designs that consider the comfort and ease of the user.

Environmental Considerations

With an increasing focus on sustainability, the manufacturing and disposal of hex drill bits will likely undergo changes:

- Recycling Initiatives: Programs that encourage recycling old or worn-out bits.

- Environmentally Friendly Manufacturing: Processes that reduce energy consumption and pollution.

Smart Technology Integration

Integration with smart technologies might shape the future of hex drill bits:

- Smart Monitoring: Bits that can provide real-time feedback on performance and wear.

- Automated Adjustments: Systems that adjust speed and pressure based on material and bit condition.

As technology continues to evolve, hex drill bits will undoubtedly adapt and innovate, shaping the future of drilling tasks and opening up new possibilities for professionals and hobbyists alike.